|

|

|

|

|

Min depth to the bottom of foundations on domestic dwellings is 0.9 of a metre, here we are at 1.4 metres depth & still going! |

An honest days graft & my back is still in one piece! |

Looking nice & neat, but still not deep enough ! the ground was too soft to build on, better safe than sorry, so got the foundation piling lads in. |

|

|

|

|

|

Starting the pile driving |

Adding on extra tube |

Wow, 10 feet deep here! |

|

|

|

|

|

Ring beam in place |

Ready for the concrete |

In she goes! |

|

|

|

|

|

Barrow service from the concrete lads |

Perfectly level |

Starting Brickwork |

|

|

|

|

|

A good old fashioned inspection chamber had to be built |

Internal flaunching over the engineering brick, with cement bag finish |

Back inlet gully & trap on pea gravel |

|

|

|

| Drain connection to under floor |

Hot & Cold feed with insulation & ducting |

Hardcore compacted at every 6" layer intervals (6 tons) |

|

|

|

| Restricted access on site, so I had the reinforcement mesh cut in two to fit through the customers gate |

And here he is, Mr Sutcliffe using his skills as a retired fitter, to weld the mesh back together with new lenghts of re-bar. Thanks John! |

A393 10mm re-bar fabric mesh, on 50mm Styrofix plastic spacers, on 80mm Quinn Therm, on 1200 gauge visqueen, on 1" blinding sand, on compacted limestone hardcore |

|

|

|

| Ready for action, with the mesh a 1/3 from the bottom of the slab. It really is a perfect job |

The free barrow service is a great idea from the concrete lads & saves my back! |

I took out some of the brickwork from the house wall & floated the concrete underneath it to achieve four sided suspension |

|

|

|

| House wall cut into & wall starter kits bolted on |

External leaf going up |

Polysterene removed & a very clean 3 course below dpm chase (I hooverd it!) |

|

|

|

| Temp door profile |

Smooth reds on the corners to give a bit of character |

I made a new flagged path around the extension sooner rather than later to keep the mud down to a minimum |

|

|

|

|

|

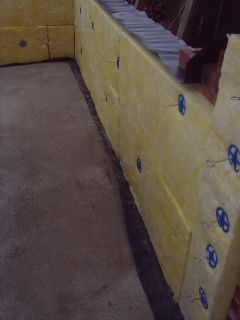

85mm full fill thermo slabs in |

A tidy bit of internal blockwork |

Spotless floor, even at this stage |

|

|

|

| Dodging the rain |

Full fill wall bats going in |

Internal wall tied into house |

|

|

|

| Small pantry window bricked up on the inside, then the outside toothed out ready for the large window move |

I removed more brick than I planned for, as the mortar in the old wall was'nt up to the job of supporting the new load, so I rebuilt it |

I did the maths & came to the conclusion that 3 acrow props would take the temporary load, but better safe than sorry with me, so I put 8 in! |

|

|

|

| I built a wooden form, then a brick archway to match in with rest of the house with cement bag finish. You can see where the old window used to be in the background. |

This is where im different to other builders... I load up the R.S.J with mortar, then force it up into the wall with acrows, instead of trying to slot bricks in above it. (Arrow is just a marker) |

I leave the props in for a few days, then hammer steel packing shims in at each end, between the gurder & pad stone, not bits of slate like the cowboys do. |

|

|

|

| Pre-fab roof trusses in, & jack rafter work. |

Facia's & Soffits in, with eaves support over external skin. |

Felt support trims in. |

|

|

|

| Starting to remove the internal wall, this is where most of the weight is, so doubled up on props, just incase. |

Floor supported, but with extra strong-boy supports in the brick courseing too, nothing drops or moves when I work on it. |

I had spacers welded into the internal beam to avoid any lateral bowing, the two beams are then bolted together. |

|

|

|

| Instead of just building up from the old window cill, I took all the brickwork out from the floor level & replaced with newboth sides, with vertical d.p,c's. An extra two days work, but worth it for peace of mind. Ties on every course. |

Before |

After

Walls removed, all the hard graft & mess done while my customers took a short break in sunny Wales! |

|

|

|

|

|

Before |

After |

Nice & Tidy |

|

|

|

|

|

Tiles going on, breathable underlay & a 5" head lap |

Roof On |

Lovely, dead straight. |

|

|

|

|

|

Building Inspector passed the structure, now ready for first fix electrics, then plastering. |

First fix in and dry lining started, all by me of course & a pic of the most useful piece of equipment I have.... two beer crates! |

Plastering started, nice & neat, no mess, no fuss. |

|

|

|

|

|

I always give my jobs at least one coat of emulsion, just so its easier for you to paint onto. |

Putting the electrics in |

A lovely simple kitchen extension |

|

|

|

|

|

Flagged around the sides |

Front elevation |

Finished Job |